Contributor: 5th Element Inspection Services LLC

Understanding Dropped Objects

Gravity doesn’t take a break. Dropped Objects continue to pose the greatest risk of serious injuries, fatalities, and equipment damage in several industries worldwide. Similar statistics apply to leisure activities and home life, too.

What is a Dropped Object?

Any item with the potential to cause injury, death, or equipment/environmental damage, that falls down or over from its previous position. Dropped objects can be further classified into two categories, static and dynamic.

When Referring to Dropped Objects, Consider:

- Hand tools being used at heights

- Hand tools/equipment left behind after working at height

- Operations conducted at height

- Equipment mounted at a height that, following contact, vibration, or environmental conditions, could fall (i.e., piping, lights, cameras, rigging gear)

- Temporary equipment at height

- Where personnel are working on a level directly below the work site

According to the Bureau of Labor Statistics, there are more than 50,000 “struck by falling object” OSHA recordables every year in the United States. This translates to roughly 116 injuries caused by falling objects every day or one injury caused by a dropped object every 10 minutes. These statistics are driven by actual reported incidents, which makes one wonder how many falling objects incidents are going unreported and not reflected in this data. While maritime operations involve a lot of overhead work, there is always the possibility of tools, equipment, work material, and other objects falling or being dropped from an elevated position.

What is OSHA’s Position on Dropped Objects (Struck-By) Prevention?

OSHA has determined that struck-by hazards are one of the four main safety hazards (OSHA’s Fatal Four), that account for most of all worker deaths each year on the job site. OSHA has set forth requirements to protect workers from struck-by objects lifted or handled hazards. These requirements are mandatory and must be implemented anywhere these struck-by hazards exist.

What Causes Dropped Objects?

- Poor housekeeping

- Scrap and debris left aloft

- No inspection

- No equipment maintenance

- Poor designs

- Weather

- No restraints

- No planning

- Load miscalculation

- Lack of risk assessment

- Errors in space requirements

- Instability

- Ineffective control of equipment or tools taken aloft

- No lanyards on tools used at height

- Improperly secured or inappropriate loads

- No regular inspection procedures

- Becoming blind to changes in activity (dynamic risk assessment)

- Carrying equipment while at height

Examples of Drops Risk Areas

- Rig derricks/drill floor

- Areas below lifting operations

- Cranes

- Elevated work areas or platforms

- Workspaces where equipment is mounted overhead

- Temporary/portable equipment

- Remotely operated vehicles (ROVs)

- Vessels/barges

- Pipe racks

- Forklift trucks

- Poor stacking of materials

- Ladders

- Scaffolding

What are the Effects of a Dropped Object?

- Injury

- Fatality

- Damage to equipment

- Damage to property

- Reputational damage

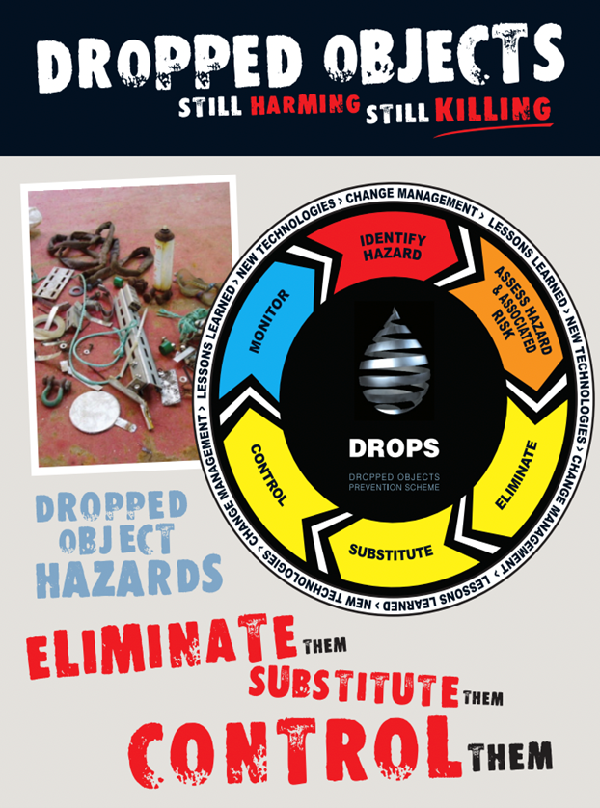

What Can We Do to Mitigate Dropped Object Risks?

Recommended Best Practices

- Create a dropped objects work group specific to the site.

- Complete a derrick or work site dropped objects inventory, for example with HAZARD ID tool.

- Use the inventory to develop an inspection program.

- Introduce working at height procedures.

- Introduce specific toolkits for working at height. Implement processes to account for tools.

- Raise overall dropped objects identification and mitigation among the workforce.

- Train relevant personnel to identify and mitigate dropped objects processes.

- Secure tools from dropping to lower levels.

- Following Job Safety Environment Assessment (JSEA) guidelines, erect signages and physical barriers to restrict access before work is conducted overhead.

- All rigging risk assessments require consideration of the risks involved in moving equipment at height.

- Review and revise JSEAs for dropped objects potential.

- Introduce regular dropped objects campaigns.

- Schedule regular Hazard Hunts.

- Review handling and securing procedures for tubular components.

- Introduce area ownership and hold personnel accountable.

- Add secondary retention, safety securing and consider safety systems, such as safety nets and safety barricading.

- Inspect personal protective equipment (PPE), for example, safety harness, lanyard and chin straps.

- Inspect all overhead equipment and locations for loose items that may present a hazard during maintenance activities especially those that cannot be tethered for example: nuts, bolts, screws, etc.

How Can I Personally Prevent Dropped Objects in the Workplace?

- Actively support the dropped objects workgroup.

- Take responsibility for my actions.

- Look after my colleagues.

- Maintain good housekeeping.

- Stop unsafe activities by using my SWA.

- Make observations and report incidents.

- Review and follow procedures.

- Recognize known hazards and follow the controls in place.

- Consider dropped objects in all Toolbox Talks.

- Consider dropped objects in all JSEAs.

- Check areas after all work is completed, even if it is permit-controlled.

- Participate in Hazard Hunts.

- Investigate all incidents, including near misses.

- Secure all tools and equipment when working at height.

Is it Worth Being Fined by OSHA/MSHA?

The choice is always yours. As a company, you have an obligation to keep your employees safe and provide a safe working environment (thereby preventing injuries and fatalities) through:

- Proactive Training

- Implementation of required OSHA standards to ensure each work area is safe

- Provide a budget for safety solutions to adhere to point 2

- Make every team member a safety champion – employees need to be cognizant that their actions not only affect their productivity and colleagues, but also themselevs and their loved ones (in the event of an injury or fatality)

Are There Solutions in the Current Market?

There are plenty. We are one of them but what makes us different?

- 5th Element is a specialized solutions provider with a combined 50+ years of hands-on operational experience in the Oil & Gas, Marine, Petrochemical/Chemical, Construction, Mining and Power Generation industry.

- We have a very niche solutions offering designed and engineered in Australia and the EU, manufactured in China, the EU and the USA.

- Our StopDrop Barricading solution is the ORIGINAL and first-to-market polymer-based barricading system adapted first by the Mining Industry followed by the Oil & Gas industry. To date, we supply to a variety of industry sectors across the globe.

- We have been providing PRACTICAL, AFFORDABLE and PROVEN safety products that WORKS.

- We can provide site assessments and safety audits to identify workplace hazards and recommend solutions.

“It takes less time to do something right, than it does to explain why you did it wrong.”

More information about 5th Element.

References/Resources

- ELCOSH

- DROPS Org

- Liberty Mutual

- OSHA