Contributor: Epicore Biosystems

This summer, it has been difficult to begin each day without being confronted by news of record-breaking heatwaves or workers suffering from heat-related injuries when turning on your preferred morning news show or browsing a news website.

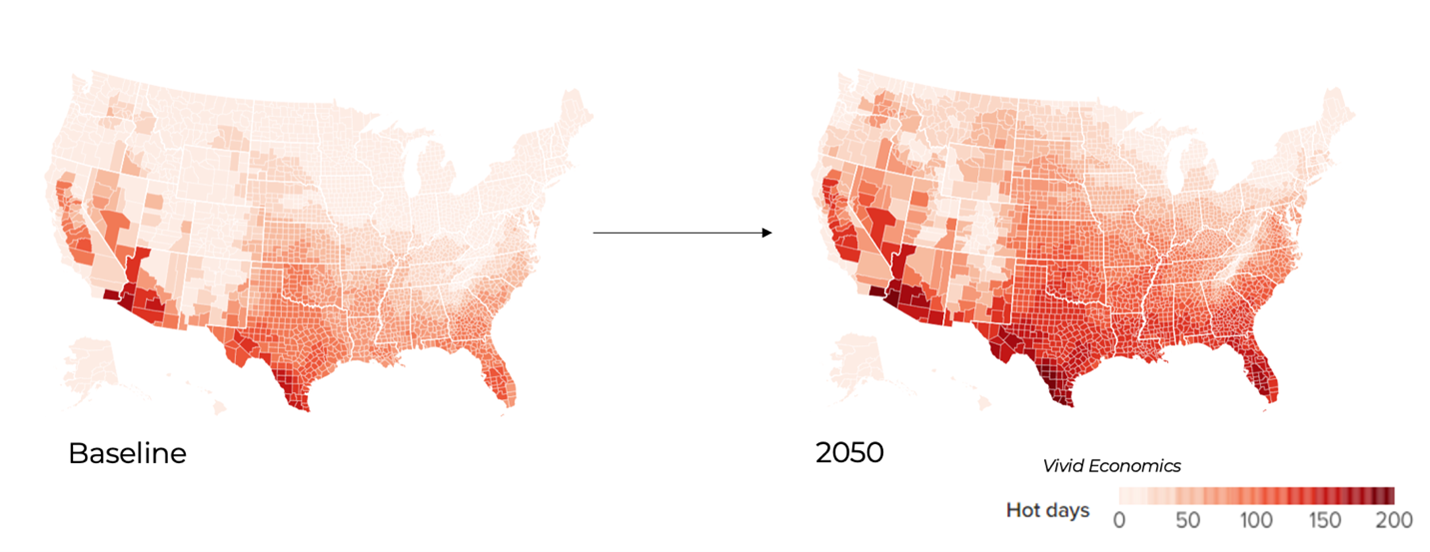

Despite the current reports of the summer of 2023 being the hottest on record, scientists are cautioning that it might actually be the least extreme among the foreseeable summers. Disturbingly, projections suggest that by 2050, there will be over 50 additional scorching days (exceeding 90°F). According to OSHA’s findings in 2021, this anticipated increase in heat will result in an alarming 450,000 more occupational injuries and a sevenfold rise in heat-related deaths. These figures are staggering, especially in light of organizations like Public Citizen (2022) suggesting that heat-related injuries and fatalities are already underreported by factors as high as 50x and 40x, respectively.

From an economic perspective, heat exerts a substantial influence. As reported by the Atlantic Council (2021), for each 1°C rise in temperature, there is a 3% reduction in efficiency. This, in turn, is anticipated to result in a staggering $500 billion in labor productivity losses. Furthermore, the RAND Corporation conducted a comprehensive study on Heat Illness prevention in California and estimated that the economic value associated with preventing each injury or illness amounts to $770,000 in 2023. These figures underscore the significant financial implications of heat-related issues.

Our bodies, however, are tropical at the base, and we have developed natural biological and physiological responses (strain) to the heat stress challenge of dissipating heat to our outside environment. These are a cardiovascular response of increasing the amount of blood flow to the skin and, most importantly, by initiating evaporative cooling, i.e., sweating.

Of course, our bodies are also amazing “machines” and over time adapt to the extra challenges we provide. In the case of heat acclimation, they become increasingly proficient at dissipating heat, characterized by an earlier onset of sweating and enhanced water and salt regulation. This adaptation includes the retention of more electrolytes, as the sweat becomes more diluted and approaches the consistency of water.

All of this adds lots of variability for each person on any given day. Your natural heat tolerance, your natural level of heat stress response with how your body is reallocating blood, your current level of heat acclimation, your level of hydration, fitness, body mass, dietary habits, alcohol consumption, workload strain, PPE, and of course the day’s temperature and humidity.

It’s no wonder we see such inter- and intra- variability from individual to individual. research findings have indicated disparities of up to tenfold in sweat losses among industrial workers during similar work sessions, even when exposed to comparable environmental conditions, wearing similar protective gear, engaging in similar activities, and working at similar intensity levels.

Now, if your role is to protect the heat-exposed workers at your company and you are in the process of constructing a heat stress program aimed at safeguarding your most vulnerable workers, how can you discern, on any given day, who within your workforce is the most susceptible and thus in need of the program’s protection? Additionally, what precise levels of protection do they require, and when should these protective measures be implemented?

The good news is there have been technological advancements to assist and empower each worker with essential health information to ensure their safety. These technologies encompass heart rate monitors (measuring cardio strain), core temperature monitors (serving as “backstops” for timely intervention with mitigation measures), and the latest addition of personal hydration smart wearables. These wearables act as preventive tools, allowing individuals to track their hydration levels (including water and salt loss) and make necessary replenishments.

Science tells us, that proper hydration (water and sodium) is essential to letting your body maximize its level of tolerance from the heat.

At Epicore Biosystems, Cambridge, MA, we are a digital health company developing advanced sweat-sensing wearables and cloud analytics that provide real-time, personalized health insights for hydration, stress, and wellness.

Our Connected Hydration system is a microfluidic-based sweat patch with a Bluetooth module designed as the first smart wearable to continuously measure sweat fluid and electrolyte losses while monitoring skin temperature and movement.

Connected Hydration is the first-ever personalized hydration management solution that:

- Tracks sweat/electrolyte loss and intake

- Alerts users at risk of dehydration

- Measures skin and under-PPE temp

- Measures activity level

The system comprises a reusable Bluetooth module, single-use microfluidic patches, a smartphone App, and Enterprise software for group/anonymous user data analysis and predictive analytics.

Features include:

- Sweat fluid & electrolyte loss, skin temp, and motion tracking

- Rehydration feedback in real-time

- Vibration lost fluid alerts and dehydration alarms

- 1000 hours of battery life

- Class 1, Division 2, Groups A, B, C and D, T6

Now with Connected Hydration, your heat stress program can continuously focus daily on who is today’s most vulnerable.

To learn more on how Epicore can help you scientifically evolve your heat stress programs please stop by the Epicore Biosystems booth, #808, at VPPPA’s 2023 Safety+ Symposium or contact [email protected] to schedule an introduction meeting.

About Epicore Biosystems

Epicore Biosystems has developed ‘skin-like’ wearable microfluidic solutions that are capable of non-invasively measuring sweat biomarkers, skin health, and physiology, in real-time. Founded in 2017 as a spinout company from Northwestern University’s Querrey Simpson Institute for Bioelectronics and John Rogers Laboratory, Epicore has partnered with multiple Fortune 500 companies, the Department of Defense, and leading research hospitals to drive personalized hydration and skin care management with wearable microfluidic products. For more information, visit the Epicore website.